Understanding the Role of Direct Reduced Iron in Steel Production

- Mohammad Reza Shoaripour

- Oct 25

- 4 min read

Steel production remains a cornerstone of modern industry. It supports construction, manufacturing, and infrastructure development worldwide. One key material in this process is reduced iron. This article explores the role and applications of reduced iron in steel production. It provides clear insights and practical information for businesses involved in petrochemicals and related sectors.

The Importance of Reduced Iron in Steel Manufacturing

Reduced iron plays a critical role in steel manufacturing. It serves as a raw material that helps produce high-quality steel efficiently. The process of reducing iron ore removes oxygen, leaving behind metallic iron. This iron is then used in various steelmaking methods.

Using reduced iron offers several advantages:

Energy efficiency: It requires less energy compared to traditional blast furnace methods.

Lower emissions: The process emits fewer greenhouse gases.

Improved quality: It produces steel with fewer impurities.

Cost-effectiveness: It reduces overall production costs.

These benefits make reduced iron a preferred choice for many steel producers aiming to optimize their operations and meet environmental standards.

Applications of Reduced Iron in Industry

Reduced iron finds applications beyond basic steelmaking. Its versatility supports various industrial needs. Here are some key applications:

Electric Arc Furnace (EAF) Steelmaking

Reduced iron is a primary feedstock in EAF steel production. It melts quickly and mixes well with scrap steel. This combination enhances furnace efficiency and steel quality.

Direct Steel Production

Some plants use reduced iron directly to produce steel without melting scrap. This method improves control over the chemical composition of the final product.

Alloy Production

Reduced iron serves as a base for producing specialized steel alloys. These alloys meet specific mechanical and chemical requirements for automotive, aerospace, and construction industries.

Petrochemical Equipment Manufacturing

Steel made from reduced iron is used to build durable equipment for petrochemical plants. Its strength and corrosion resistance are vital for handling harsh chemicals.

Infrastructure Projects

Bridges, buildings, and pipelines often rely on steel derived from reduced iron. The material’s consistency ensures structural integrity and longevity.

Understanding these applications helps businesses identify opportunities to integrate reduced iron into their supply chains and production processes.

What is the difference between pig iron and direct reduced iron?

Pig iron and direct reduced iron (DRI) are both intermediate products in steelmaking but differ significantly in production and properties.

Pig Iron

Produced in a blast furnace by smelting iron ore with coke and limestone. It contains high carbon content (around 3.5-4.5%) and impurities like sulfur and phosphorus. Pig iron is brittle and requires further refining to become steel.

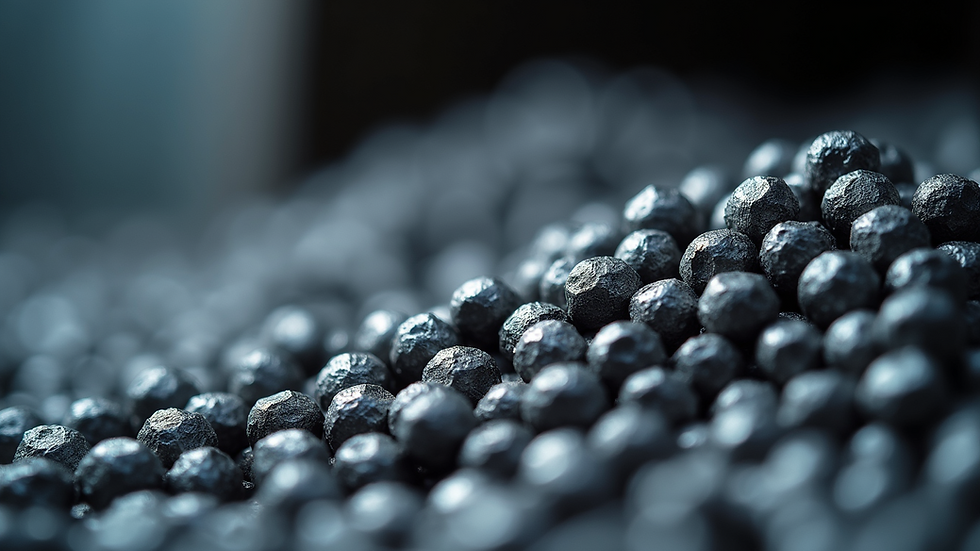

Direct Reduced Iron

Made by reducing iron ore using natural gas or coal at lower temperatures without melting. It has a lower carbon content and fewer impurities. DRI is porous and sponge-like, making it easier to melt and refine in electric arc furnaces.

The choice between pig iron and DRI depends on factors such as energy availability, environmental regulations, and desired steel quality. DRI offers a cleaner and more flexible alternative, especially in regions with access to natural gas.

How Reduced Iron Enhances Sustainability in Steel Production

Sustainability is a growing concern in heavy industries. Steel production traditionally consumes large amounts of energy and emits significant carbon dioxide. Reduced iron contributes to greener steelmaking in several ways:

Lower Carbon Footprint

The reduction process uses natural gas or coal more efficiently than blast furnaces. This results in fewer CO2 emissions per ton of steel produced.

Energy Savings

Reduced iron requires less energy to melt in electric arc furnaces compared to pig iron or scrap steel alone.

Resource Efficiency

It allows the use of lower-grade iron ores that might otherwise be wasted.

Recycling Compatibility

DRI can be combined with scrap steel, promoting circular economy practices.

Businesses aiming to meet environmental standards and reduce operational costs should consider integrating reduced iron into their steel supply chains.

Practical Recommendations for Businesses Using Reduced Iron

For companies involved in petrochemicals and related industries, sourcing steel made with reduced iron can improve product quality and sustainability. Here are actionable recommendations:

Partner with Reliable Suppliers

Choose suppliers who provide certified reduced iron products. Verify their production methods and environmental compliance.

Optimize Supply Chain Logistics

Plan for timely delivery and storage of reduced iron to maintain its quality and reduce handling costs.

Invest in Quality Control

Implement testing protocols to ensure steel meets required specifications for strength and durability.

Explore Collaborative Innovation

Work with steel producers to develop customized alloys suited for petrochemical equipment.

Monitor Market Trends

Stay informed about advances in reduced iron technology and regulatory changes affecting steel production.

By following these steps, businesses can leverage the benefits of reduced iron to enhance their operations and product offerings.

Future Trends in Reduced Iron and Steel Production

The steel industry continues to evolve with technological advancements and environmental pressures. Key trends shaping the future include:

Increased Use of Hydrogen

Hydrogen is emerging as a clean reducing agent, potentially replacing natural gas in producing reduced iron.

Digitalization and Automation

Smart manufacturing techniques improve process control and efficiency in steel plants.

Circular Economy Models

Greater emphasis on recycling and reuse of steel materials reduces reliance on virgin iron ore.

Global Supply Chain Diversification

Companies seek multiple sources of reduced iron to mitigate risks and ensure steady supply.

Stricter Environmental Regulations

Compliance drives innovation in low-emission steelmaking technologies.

Staying ahead of these trends will help businesses maintain competitiveness and sustainability in the long term.

Using direct reduced iron in steel production offers clear advantages in efficiency, quality, and environmental impact. Understanding its role and applications enables businesses to make informed decisions and capitalize on emerging opportunities in the steel and petrochemical sectors.

Comments